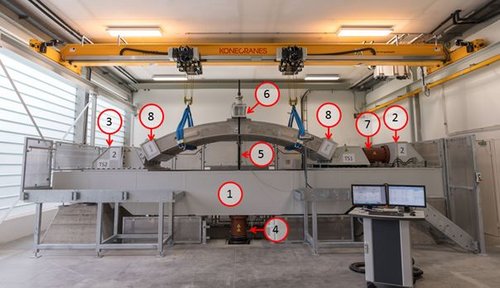

Lining segment test stand

Tubbings are precast concrete elements which, when assembled into rings, are used for the lining of the newly excavated tunnel.

Tasks of the segment:

- Securing and supporting the tunnel

- Absorption of the driving forces of the TBM

- Final lining in the case of single-shell construction

Biaxial load tests can be carried out on the segment test rig to determine the load-bearing and deformation behavior. Thanks to its modular design, it can be adapted to a wide variety of segment geometries and dimensions.

For the safe operation of tunnels over decades, knowledge about the degree of utilization of the installed lining is of great importance. In order to be able to make precise statements about the deformation and load-bearing behavior when using precast reinforced concrete elements, so-called tubbings, tests on a scale of 1:1 under laboratory conditions and precisely defined load collectives are necessary. Therefore, in close cooperation with the experts of ÖBB Infrastruktur AG and the University of Leoben, Chair of Subsurface Engineering, a test rig unique in Austria was designed and implemented to fulfill this task. This test rig allows biaxial tests to be carried out on real segments under laboratory conditions, and the knowledge gained from these tests is used to optimize the segments, the construction method and the materials used.

The segment test rig consists of two main girders (1), to which the floating (2) and fixed (3) bearings are bolted. Due to the modular design - sliding bearings - tests on segments with different chord lengths are possible. The tunnel diameters that can be tested range from 4.0 m to 6.5 m for four-section segments and from 5.6 m to 10.5 m for six-section segments. The maximum possible tunnel segment width is 2.15 m. The vertical forces are transmitted via two 1 MN hydraulic cylinders (4) to tie rods (5) and then to the crosshead (6). The horizontal force is applied via two 2 MN hydraulic cylinders (7). The hydraulic cylinders have a maximum stroke length of 200 mm. The segment shoes (8) form the link between the segment to be tested and the test rig. The total mass of the test rig without the segment is approx. 52 t, of which 27 t is accounted for by the steel structure. The segment itself weighs up to 12 t.

Strain gauges and inductive displacement transducers

Vertical and horizontal force application

Deformation measurement systems

Segment after examination, controlled destruction